Touch technology in smartphones explained

Which touch technologies are used in today’s smartphones and tablets? What separates a touch technology in one smartphone from another? And what is “in-cell touch” in the iPhone 5 and “on-cell touch” in Samsung’s Super AMOLED displays? FlatpanelsHD guides you through modern touch technology and explains why our devices will become much thinner in the coming months and years.Modern touch technology explained

Just as the original iPhone started a move towards capacitive touch, the iPhone 5 could start a move towards in-cell capacitive touchTouch technology has been around for many years but in the recent 4-5 years we have seen a surge in adoption led by smartphones and recently tablets. With the introduction of the original Apple iPhone we saw companies switch almost entirely to so-called capacitive touch technology. Before the iPhone manufacturers had primarily been using resistive touch technology and some touch screens outside of the mobile world even used infrared touch technology.

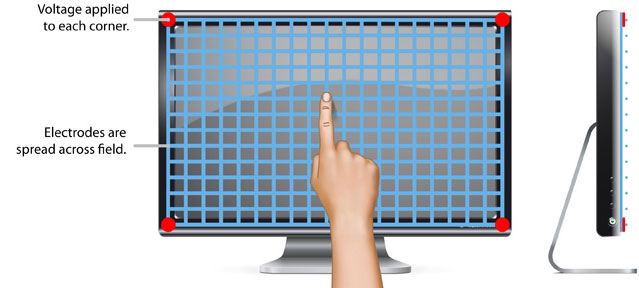

Capacitive touch is the norm today and is pretty much used in every smartphone or tablet available. This article is therefore focused on capacitive touch technology and the new variants that are about to change the industry. Before we start we need to know what a capacitive touch screen is. Basically, a capacitive touch screen is a grid of tiny, transparent electrodes. Both vertical and horizontal rows of electrodes are positioned and everywhere they overlap a capacitor is created. The human body is an electrical conductor and when you touch the screen with your finger, it is measurable because the touch sensor controller can react to the change in the electrostatic field.

Because capacitive touch technology measures directly on a layer it is not dependent on measurements from the edges of the screen such as for example infrared. Thus, capacitive technology supports multi-touch (it can register simultaneous touch points on the capacitive layer).

A capacitive touch screen illustrated. The grid pattern can be made in many ways and it is an art to make it 100 % invisible, picture credit: NextWindow

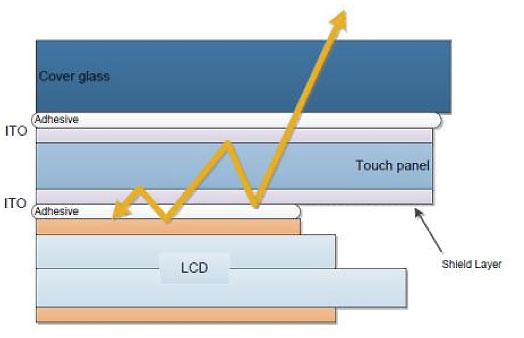

On the majority of touch displays produced today the touch layer is sandwiched between the actual LCD display panel at the bottom and a cover layer on the top – for example glass (most often Corning’s Gorilla glass). Between the display panel and the touch screen there is typically an air gap to make sure that the display and touch layer do not affect each other.

Here you see how the touch layer is placed between the LCD panel and an outer protective glass layer

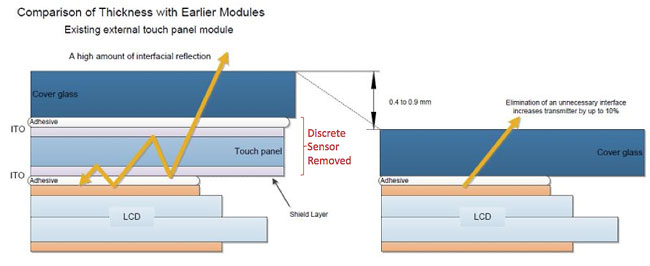

What we have learned so far from the short introduction is that capacitive touch technology requires an extra layer on top of the actual screen. But why not built touch technology directly into the display panel or into the top glass layer? Well, that is actually what we intend to talk about in this article as it is happening right now in the industry with two different types of approaches.

Recently we have started hearing about in-cell (used in the new iPhone 5 where it is called integrated touch) and on-cell (used in LG’s coming smartphones and Samsung’s Super AMOLED displays) touch technology. In-cell and on-cell (also called G2) are two different approaches, with in-cell being the most difficult to produce. Both can help to slim down displays significantly and improve color saturation.In-cell vs. on-cell

As seen in the picture above manufacturers usually use three layers. Why? Well, because LCD manufacturers produce the LCD panel, touch sensor manufacturers produce the touch screen layer and glass manufacturers (such as Corning) produce the protective outer glass. But instead you can actually move the touch technology onto the outer glass layer. This is called on-cell or G2. You can also choose to put the touch sensors into the actual display panel. This is called in-cell. Both layers are perfectly suited for the touch electrodes.

Samsung has used on-cell touch technology in their Super AMOLED displays for some time now, including in the Galaxy SIII

With on-cell the challenge is to deposit the electrodes on gorilla glass which is a type of strengthened glass. The steps to first strengthen the glass and then apply the touch technology are more difficult than producing a separate touch layer as have been done in the past.When moving to in-cell and on-cell touch technology you can expect much thinner smartphones and tablets with better displays

With in-cell the electrodes have to be deposited on a glass layer inside the LCD panel. This has two major challenges involved. First, placing touch capacitors that rely on electrodes inside the display - that also relies on electrodes - can cause noise. Second, when integrating touch directly into the display a defective display – or touch implementation – often makes the entire module unusable. With on-cell you can just scrap the glass layer and before that, when three layers was used, you had the touch technology on a completely separate layer.

By removing the touch layer display panels can become much slimmer. Here you see how Synaptics have removed the touch layer and created an in-cell display panel with better light transmittance, source: Synaptics

In-cell and on-cell touch screen production is ramping up now and in the next few months and years we will see significantly thinner smartphones and tablets, based on both in-cell and on-cell. Here are some examples of existing smartphones utilizing the new touch technologies:

iPhone 5 is one of the first phones to utilize in-cell touch technology, and it is one of the reasons for it being so thin

The future is already here

So what should you expect? As said, much thinner phones. Not only are the touch sensors closer to the displays, the displays are also becoming thinner due to a number of reasons and Gorilla glass was recently slimmed down to 0.5 mm. With both on-cell and in-cell you can also expect better color saturation as light has to pass through fewer layers. Depending on the implementation it can even make touch feedback more accurate. And lastly, on-cell and in-cell makes it feel like you are actually touching your phone’s display instead of an outer glass layer. The iPhone 4 or 4S is a good reference as it is a very popular smartphone; notice how the display is actually lowered into the phone. With in-cell and on-cell you will almost touch your display.And let us conclude with a logical question; why not just choose one? Actually, that is a question of money. Touch screen manufacturers such as Wintek and TPK have typically produced the touch layer and can continue to produce the on-cell variant in some instances. But with in-cell the touch technology is moved into the display, thus making display makers such as Samsung, LG, Sharp and Japan Display manufacturers of both display and touch module. More money for them as it would practically leave traditional touch manufacturers with no business. So, traditional touch manufacturers support on-cell and display manufacturers tend to support, unsurprisingly, in-cell.

- Sources: Synaptics, NextWindow, The Verge, Wikipedia, Samsung, Apple